Precision Micromanufacturing: Revolutionizing Industrial Production

Miniaturization trends are reshaping industrial landscapes, with precision micromanufacturing emerging as a game-changing force. This innovative approach to production is transforming how businesses create components, driving efficiency, and opening new frontiers in product design. As industries grapple with demands for smaller, more complex parts, micromanufacturing offers solutions that were once thought impossible.

The evolution of micromanufacturing has been driven by advances in materials science, precision engineering, and nanotechnology. Early applications were limited by the available tools and materials, but recent breakthroughs have dramatically expanded the scope of what’s possible. Today, manufacturers can create intricate structures with features measured in micrometers, enabling the production of highly specialized components that were previously unfeasible.

Key Technologies Driving Micromanufacturing

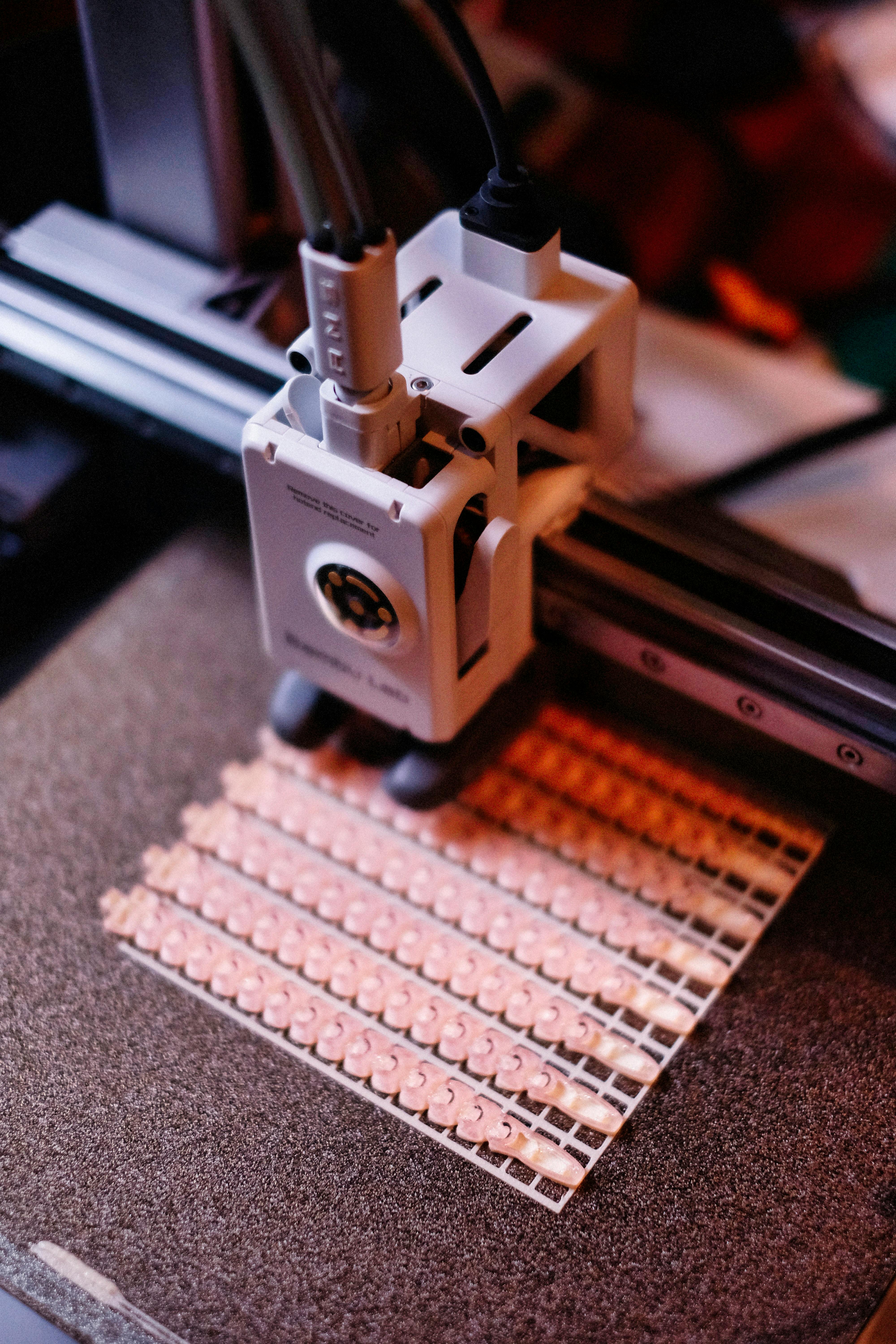

At the heart of precision micromanufacturing are several cutting-edge technologies that enable unprecedented levels of precision and control. Micro-electrical discharge machining (Micro-EDM) uses electrical discharges to erode material with extreme accuracy, allowing for the creation of complex 3D microstructures. Laser micromachining employs focused laser beams to ablate material with sub-micron precision, ideal for creating fine details and patterns.

Another critical technology is micro-injection molding, which allows for the mass production of microscopic plastic components. This process has revolutionized industries like medical device manufacturing, enabling the creation of tiny, complex parts in large volumes. Additionally, additive manufacturing techniques like two-photon polymerization have pushed the boundaries of 3D printing to the nanoscale, allowing for the fabrication of intricate structures with features as small as 100 nanometers.

Applications Across Industries

The impact of precision micromanufacturing is being felt across a diverse range of industries. In healthcare, micromanufactured components are enabling the development of minimally invasive surgical tools, advanced drug delivery systems, and miniaturized implantable devices. These innovations are improving patient outcomes and opening new avenues for treatment.

In the aerospace sector, micromanufacturing is facilitating the production of lighter, more efficient components for aircraft and spacecraft. Micro-sensors and actuators manufactured at this scale are enhancing the performance and reliability of aerospace systems while reducing overall weight and fuel consumption.

Consumer electronics have perhaps seen the most visible impact of micromanufacturing. The miniaturization of components has led to smaller, more powerful devices with enhanced functionality. From smartphones to wearable technology, the ability to pack more features into smaller form factors is directly attributable to advancements in micromanufacturing techniques.

Challenges and Limitations

While the potential of precision micromanufacturing is immense, it is not without its challenges. One of the primary hurdles is the high initial investment required for specialized equipment and facilities. The precision nature of the work demands clean room environments and highly sophisticated machinery, which can be prohibitively expensive for smaller manufacturers.

Quality control and inspection present another significant challenge. At such small scales, traditional inspection methods are often inadequate, necessitating the development of new techniques and technologies for ensuring product quality and consistency. Additionally, the handling and assembly of microscopic components require specialized tools and processes, adding complexity to the manufacturing process.

Material limitations also pose challenges. Not all materials are suitable for micromanufacturing processes, and those that are may behave differently at microscopic scales. This necessitates ongoing research into new materials and manufacturing techniques to expand the possibilities of micromanufacturing.

Future Prospects and Industry Implications

The future of precision micromanufacturing looks promising, with ongoing research and development aimed at overcoming current limitations. Advances in nanotechnology and materials science are expected to push the boundaries of what’s possible, potentially leading to the development of even smaller and more complex components.

As the technology matures, we can expect to see wider adoption across industries, potentially leading to more affordable and accessible micromanufacturing capabilities. This could democratize production, allowing smaller companies to compete in markets previously dominated by large corporations with significant R&D budgets.

The integration of artificial intelligence and machine learning into micromanufacturing processes is another exciting prospect. These technologies could optimize production processes, improve quality control, and even enable self-correcting manufacturing systems capable of adapting to changing conditions in real-time.

Strategies for Implementing Micromanufacturing

• Conduct a thorough cost-benefit analysis to determine if micromanufacturing aligns with your business goals

• Invest in workforce training to develop the specialized skills required for micromanufacturing

• Collaborate with research institutions to stay abreast of the latest developments in the field

• Consider partnering with specialized micromanufacturing service providers to reduce initial investment costs

• Implement rigorous quality control processes tailored to microscale production

As precision micromanufacturing continues to evolve, it promises to reshape industrial production fundamentally. By enabling the creation of smaller, more complex, and highly specialized components, this technology is opening new frontiers in product design and functionality. While challenges remain, the potential benefits in terms of innovation, efficiency, and competitiveness make micromanufacturing a critical area for businesses to watch and explore. As industries adapt to this new paradigm, those who successfully leverage micromanufacturing capabilities will be well-positioned to lead in their respective markets.